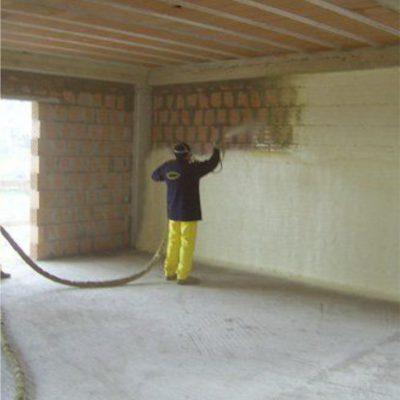

Application of polyurethane for building uses in Naples

Nowadays, waterproof coverings must have technical peculiarities no longer negotiable: they must maintain their efficiency over time, even in the presence of increasingly severe mechanical stress (pedestrian transit, event action and high loads), physical (excursions to thermal shock, pressure and condensation of vapors), chemical (acids, solvents and hydrocarbons) and biological (actions of plant roots and microorganisms). The combined action of these factors produces an acceleration of the aging process of the waterproof covering and attached thermal insulation, up to cause its collapse.

In order to avoid any risk and danger for buildings and manufactures of various nature, it is necessary to entrust the works to highly qualified companies in the field of waterproofing and thermo-acoustic insulation, such as Tecnopur.

Thanks to years of intense and constant research, the company has been able to give birth to Puretan, a particular type of polyurethane for building uses, able to respond to all the extreme operating conditions required.

insufflation of the cavity

- it achieves excellent thermal insulation of external walls with considerable benefit for living comfort and consequent energy saving;

- it considerably reduces noise transmission;

- it eliminates the formation of moving air foils inside the cavity, which are harmful for the effectiveness of the thermal insulation with consequent formation of condensation and mold;

- allows a complete transpiration of the wall allowing the migration of vapors to the outside;

- gives greater solidity to the walls, as a complete bonding is obtained between them, and to the supporting structure;

- eliminates any possibility of nesting of small insects or animals;

- completely seals the cavities;

- is physiologically inert, insoluble, not metabolizable, does not emit toxic fumes or vapors.

| Trials | Norm | Measure | Average value |

|---|---|---|---|

| Density | EN ISO 2811-1 | Kg/mc | 19 |

| Thermal conductivity | UNI EN 14315-1:2013 All.C | W/m.K | 0,035 |

| Resistance to water vapor diffusion | UNI 8054 | µ | 5 |

| Compressive strength | UNI 6350 | Kg/cmq | 0,3 |

Tompagno walls

- an excellent thermal insulation of the external walls is obtained with considerable benefit for the living comfort and consequent energy saving;

- it is a closed-cell product, therefore waterproof;

- it considerably reduces noise transmission;

- it eliminates the formation of moving air foils inside the cavity, which are harmful to the effectiveness of the thermal insulation;

- can be applied in the desired thickness, continuously without thermal bridges;

- allows a complete transpiration of the wall allowing the migration of vapors to the outside;

- it gives greater solidity to the walls, as it is completely bonded to the supporting structure;

- has an excellent adhesion such as to make a single body with almost all materials;

- completely seals the cavities;

- is physiologically inert, insoluble, not metabolizable, does not emit toxic fumes or vapors.

| Trials | Norm | Measure | Average value |

|---|---|---|---|

| Density | ISO R 845 | Kg/mc | 35 |

| Thermal conductivity | ASTM C177 | W/m.K | 0,022 |

| Resistance to water vapor diffusion | UNI 8054 | µ | 60 |

| Compressive strength | UNI 6350 | Kg/cmq | 2 |

Asbestos remediation

| Trials | Norm | Measure | Average value |

|---|---|---|---|

| Specific weight | ISO 1.23 | 1.12:1.13 | |

| Viscosity | ISO 150:250 cps | mPas a 20C | 180:220 |

| Cataltax ratio | 01:01 | ||

| Reaction time: Gel Time | 5 sec | ||

| Response time: Tack Free Time | 19:23 sec | ||

| Thickness returned | UNI 9564 (8.6.2.) | cm | 02-mar |

| Density | UNI 6349 | Kg/m3 | 67.5 |

| Adhesion to asbestos-cement | UNI 10686 | MPa | 0.8 |

| Freeze-thaw resistance | UNI 10686 | No bubbles, no flaking. Thickness unchanged. No cracking. | |

| Sun-rain resistance | UNI 10686 | No bubbles, no flaking. Thickness unchanged. | |

| Waterproofing and accelerated aging | UNI 10686 | No bubbles, no flaking. Thickness unchanged. No loss. | |

| Reaction to fire | UNI 8457 | class | 1 |

| Impermeability to water | UNI 10686 | No loss. |

Thermal insulation and roof waterproofing

| Trials | Norm | Measure | Average value |

|---|---|---|---|

| Specific weight | POL. 1.12:1.13 | ||

| ISO. 1.23 | |||

| Viscosity | mPas a 20C | POL.180:220 | |

| ISO 150:250 cps | |||

| Cataltax ratio | 01:01 | ||

| Response time: Gel Time | 12 sec | ||

| Response time: Cream Time | 4 sec | ||

| Density | PeEN 14315-2 | Kg/m3 | 50-70 |

| Adhesion to concrete | UNI 9564 | KPa | 282 |

| Adhesion to wood | UNI 9564 | KPa | 266 |

| Grip on mild steel | UNI 9564 | KPa | 286 |

| Compressive strength | UNI 6350 | Kg/cm2 | 3.29-5.76 (max) |

| Initial thermal conductivity | PrEN 14315 e 14318-1 | W/Mk | 0.025-0.027 |

| Reaction to fire | EN 13501 | Euroclass | C-D-E |

| Water vapor transmission | EN 12086 A method | mg/Pa.m.s | 30-40 |

| Impermeability to water | No loss | ||

| Tensile strength | UNI 8071 | KPa | 391.46 |

Waterproofing for roofs

| Features | Unit | Valore | Metodo |

|---|---|---|---|

| Density | Kg/m³ | 1000 | DIN 53 420 |

| Hardness at 25 ° C | Shore A | 93 | DIN 53 505 |

| Hardness at 25 ° C | Shore D | 42 | DIN 53 505 |

| Traction (elongation at break 425%) | N/mm² | 21 | DIN 53 504 |

| Traction (100% elongation) | N/mm² | 12,4 | DIN 53 504 |

| Traction (elongation 300%) | N/mm² | 15,2 | DIN 53 504 |

| Laceration | N/mm | 58 | DIN 53 515 |

| Adhesion to steel (without primer) | N/mm² | 6,5 | ISO 4624 |

| Flexural strength 5% | N/mm² | 6,3 | ASTM D 790 |

| Flexural strength 10% | N/mm² | 6,9 | ASTM D 790 |

| Adhesion to concrete | MPa | <3 | UNI EN 1542 |

| Thermal compatibility: adhesion; after 50 freeze and thaw cycles |

MPa | <3 | UNI EN 1542 UNI EN 13687/2 |

| Crack bridging ability a 23° C: static; dynamic |

Class | A₅ B₄.₂ | UNI EN 1062/7 UNI EN 1504/2 UNI EN 1504/2 |

| Resistance to positive hydraulic thrust | Bar | 5 | UNI EN 12390/8 |

| Resistance to negative hydraulic pressure | Bar | 2,5 | UNI EN 8298/8 |

| Permeability to water vapor | Sd | < 9m | UNI EN ISO 7783/1 |

| Permeability to CO₂ | Sd | > 100m | UNI EN 1062/6 |

| Slip / creep resistance | Class | Class I: 23 units Class II : 56 unit |

UNI EN 13036/4 |

| Resistance to artificial atmospheric agents | Hours | 2000 hours (of UV rays and condensation) | UNI EN 1062/11 |

| Abrasion resistance | Mg | < 120 | UNI EN ISO 5470/1 |

| Impact resistance | N·m | > 30 | UNI EN ISO 6272 |

Foundation treatment with polyurethane foam applied by spraying

Via Caserta al Bravo, 184 – 80184 NAPOLI

Tel. +39 081 7383600 – Fax +39 081 7383873

FOLLOW US ON

OPENING TIME

From Monday to Friday from 9:00 to 18:00

on Saturday and Sunday closed